An industry leader for over 30 years

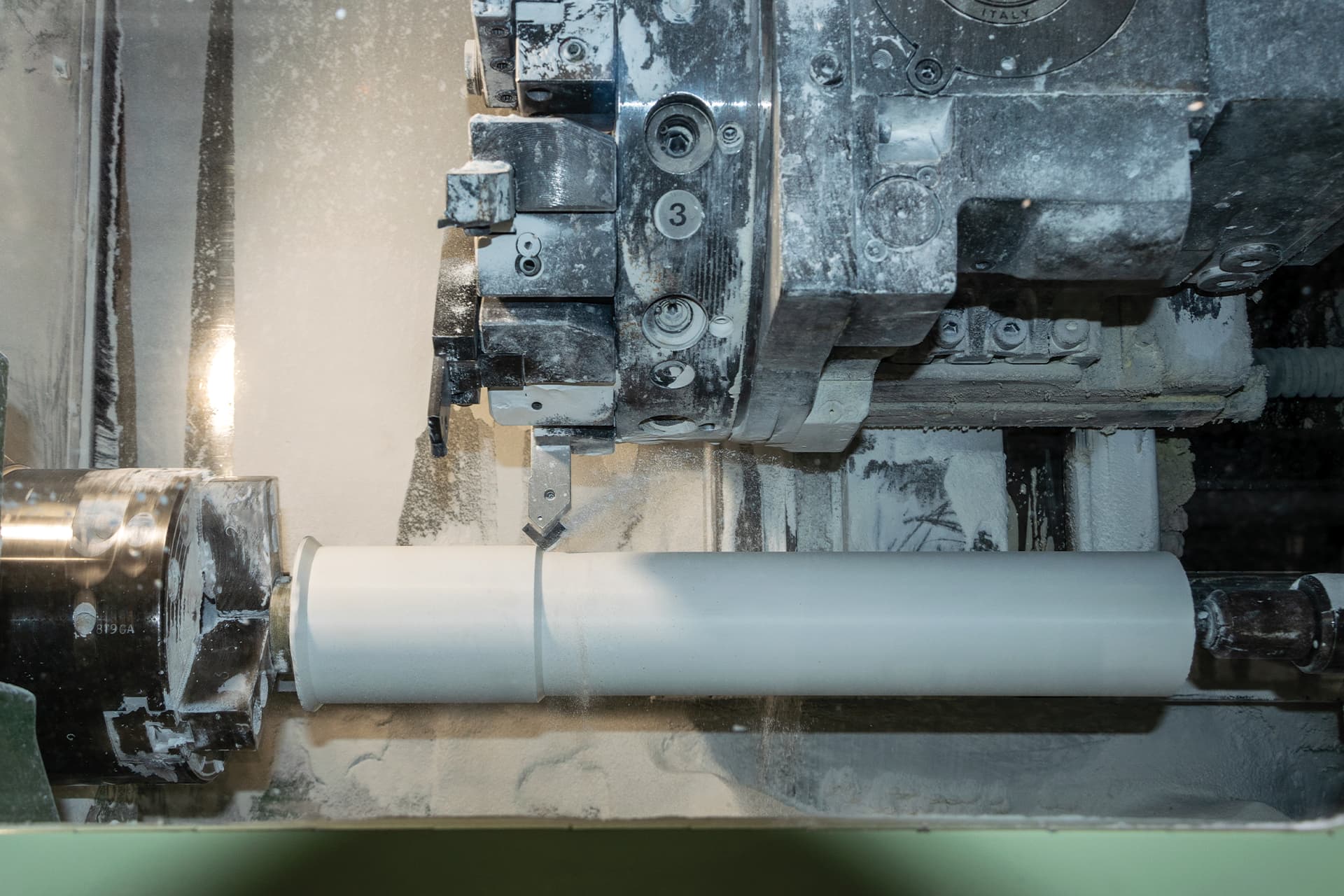

Around the year 2000, market leader HTC Ceramics diversified its production methods with axial pressing and injection technology to produce large batches of spark plugs. It is precisely here that the majority of pistons and technical ceramics are produced.

Consultancy and Know-How

The grinding and atomisation plant was relocated to Terno d’Isola at REDCO, where the production of ceramics for spark plugs was also relocated.

We support the customer from the earliest stages of prototype design, following them step by step in the development of the prototype, adhering strictly to specifications and ensuring the production of a very wide range of items.

Customisation has made us highly competitive

Our mission has always been:

“improve customers’ competitiveness by producing functional ceramic components with high performance, quality and dimensional accuracy.”

Today we supply a wide range of sectors and items, including piston pumps and volumetric pumps, electrical resistors, the food sector, where we supply ceramic components for homogenisers, taps, wire, the foundries and die castings, pharmaceutical, agricultural, automotive, insulators, thermocouples, sealing rings, nozzles etc.

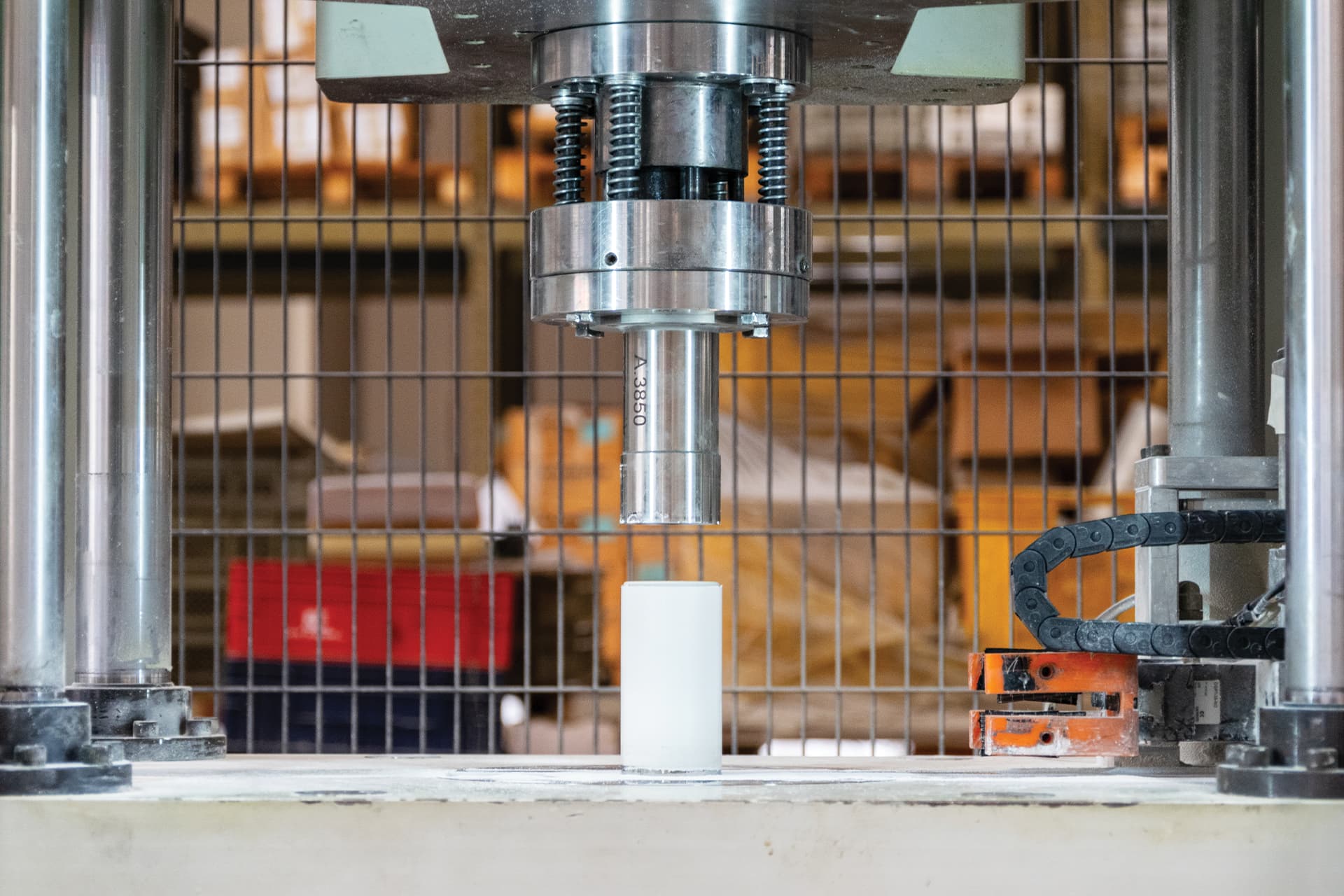

Industry 4.0 & Flexibility

We have been incorporating Industry 4.0 for several years now as a response to an increasing demand for customisation.

Industry 4.0 has allowed us to be more and more customer-oriented, as the flexibility of the plants is such that they allow more and more tailor-made production.

The inclusion of high-powered machines in the production process, which can communicate with each other, reducing processing times and optimising the production chain, has also allowed us to increase efficiency.

The Group, the People, the Future

For us, 2023 does not only mean the purchase of new quality control machines that allow in-process and post-process inspection of workpieces, but also a huge focus on people, with constant training and continuous growth projects. In addition, energy efficiency is planned thanks to solar panels that will be installed above the premises. Around 7000 square metres of total production space and an exponential growth in market share make us a valid and efficient solution to technical ceramics made in Italy.

Circa 7000 mq totali di spazio produttivo e una crescita esponenziale di quota di mercato ci rendono una valida ed efficiente risposta alla ceramica tecnica made in Italy.

Sectors

The many peculiarities of ceramics are moulded in various sectors, from food to pharmaceuticals via industry and agriculture.

Hardness, resistance to high temperatures and low thermal conductivity make this material suitable for a large number of artefacts.